Thermoformed Packaging and Tooling

09, 14

Orion Product Development Case Study – Thermoformed Packaging and Tooling

by kevin urquhart 0 comments

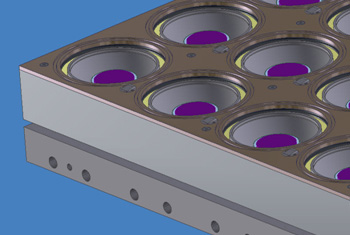

Orion Product Development Case Study - Thermoformed Packaging and Tooling

We were requested to provide design engineering services for a number of innovative new product and tooling designs by this major international player in the food packaging industry, leveraging our significant previous experience in this area. Each project involved idea generation, concept design, detail design, engineering drawing and photorealistic rendering in the case of product designs. Typical project values were several £100K each, with end customers being major UK and international fast food chains and supermarkets, such as McDonald's and Sainsbury'sI worked with Kevin on the Management Team at a mutual former company, so was keen to engage him when we have had an urgent skills shortage for several new product and tooling development projects. I find him to be extremely versatile, proficient and reliable, and he always delivers what is requested efficiently and to a very high standard. I would have no hesitation in engaging him again or recommending him to others.

Thermoformed Product and Tooling, Plant Manager

09, 14

Orion Product Development Case Study – Marine Renewables, Trenching and Mining

by kevin urquhart 0 comments

Orion Product Development Case Study - Marine Renewables, Trenching and Mining

Kevin worked with us at a Senior Engineer level on several new product development projects within the Trenching, Renewables and Subsea Mining Divisions. He is extremely innovative, technically proficient and diligent, and therefore adds significant value to any given project. I would have no hesitation in engaging him again or recommending him to others

Former Technical Director, SMD

All pictures in this article used by kind permission of SMD Ltd.